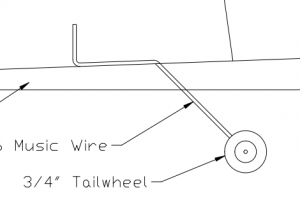

Usually, when fitting a tailwheel or skid to a profile fuselage the method shown on the plan is often to simply poke a hole in the fuselage to accept the wire and glue it in place. It never struck me as being a satisfactory way of fixing a skid particularly if you attach the skid to a self-launching device.

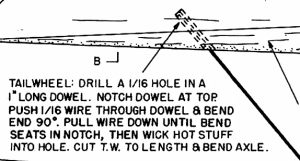

Another method I’ve seen is to drill a hole into the fuselage to accept a dowel with the wire skid running through the dowel.

The first problem I had with this method is the practicality of getting the fuselage into my drill press to drill the hole at the angle shown and to be sure I get the hole square. The second was drilling a hole in the centre of a small piece of dowel.

Some time ago I came across a better way to fit wire tailwheels or tail skids to profile models.

First, sandwich your skid between two pieces of balsa. Note the angle at the end of the wire which stops it from twisting. I use epoxy for this job. The whole job was clamped into a vice while the epoxy cures.

Once the epoxy is cured cut a slot in the profile fuselage wide enough to accept the balsa covered end of the skid with a nice snug fit.